ABS 3D Printer Filament, Blue Color, ABS 1kg Spool 1.75mm Filament

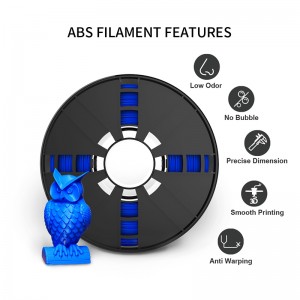

Product Features

ABS is a highly impact-resistant, heat-resistant filament that produces strong, attractive designs. A favorite for functional prototyping, ABS looks great with or without polishing. Push your ingenuity to the limit and let you creativity take flight.

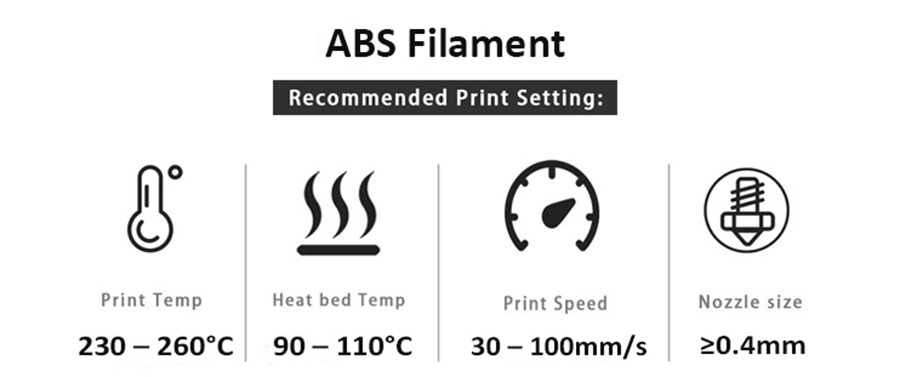

Recommended Extrusion/Nozzle Temp: 230 °C - 260°C (450℉~ 500℉ ),

Heated Bed Temp: 80°C - 110 °C (176℉~ 212℉)/ PVP stick helps.

Printing Speed: 30~100 mm/s (1,800~4,200mm/ min).

Fan: Low for better surface quality; Off for better strength.

Filaments Diameter and Accuracy: 1.75 mm +/- 0.05.

Filaments Net Weight: 1 kg (2.2 lbs)

| Brand | Torwell |

| Material | QiMei PA747 |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.03mm |

| Length | 1.75mm(1kg) = 410m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 70˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV, SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

More Colors

Color Available

General Colors: White, Black, Red, Blue, Yellow, Green, Nature, Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent

Fluorescent Colors: Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue

Luminous/Glow in Dark Colors: Luminous/glow in dark Green, Luminous/glow in dark Blue

Color Changing via Temperature Series: Blue green to yellow green, Blue to white, Purple to Pink, Grey to White

Accept Customer PMS Color

Model Show

Package

1kg roll ABS filament with desiccant in vaccum package.

Each spool in individual box (Torwell box, Neutral box, or Customized box available).

8boxes per carton (carton size 44x44x19cm).

More Information

No material is exactly the same and the specifications vary, there are a few things that should definitely help:

- Enclose the printer: ABS is sensitive to temperature changes, it is better to make sure your 3D printer is either enclosed or at least that the temperature of the room is not cold.

- Use a heated bed: This is mandatory. ABS has a high thermal contraction, when the first layer cools down it shrinks in volume, causing deformations like warping. With a heated bed at around 110 °C, ABS remains in a sort of rubbery state, allowing it to contract without deforming.

- Proper bed adhesion: It’s highly recommended to use an adhesion agent on the build plate in addition to a heated bed. There are plenty of options, including glue stick, Kapton tape, and ABS slurry, a liquid solution of ABS diluted in acetone.

- Fine-tune the cooling: The part-cooling fan blows air onto each layer for faster solidification, but for ABS, this can lead to deformation. Try adjusting the cooling settings for the bare minimum necessary for bridging and to avoid stringing. A good tactic is to turn off the cooling fan entirely for the first few layers.

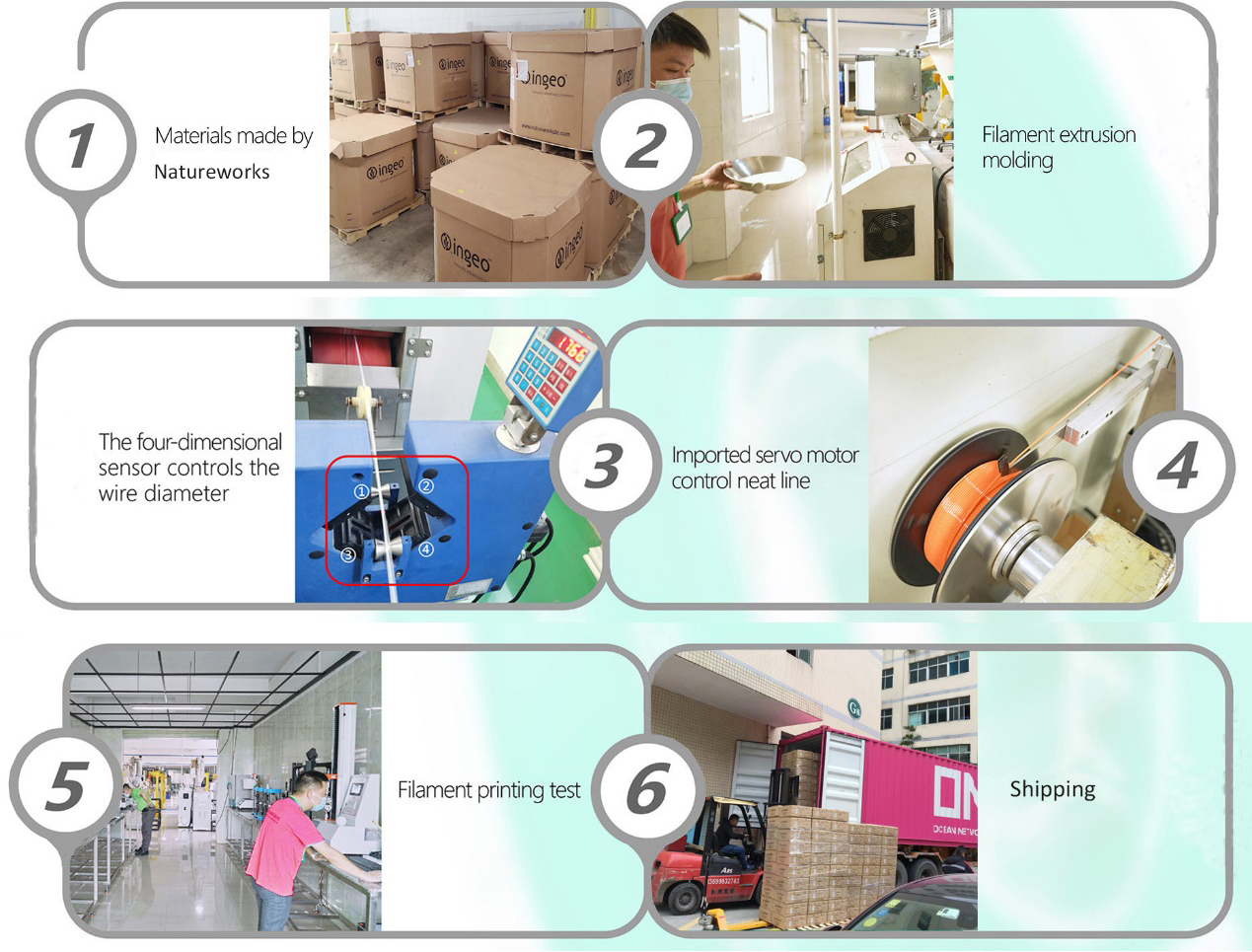

Factory Facility

Torwell, an excellent manufacturer with more than 10years experiences on 3D printing filament

Important Note

Please pass the filament through the fixed hole to avoid tangles after use. 1.75 ABS filament requires a heat-bed and a proper printing surface to avoid warping. Big parts are prone to warp in domestic printers and odor when printed is stronger than with PLA. Using raft or brim or reduce the speed for the first layer could help avoid warping.

Why choose Torwell ABS Filament?

Materials

No matter what your latest project calls for, we have a filament to suit any need, from heat resistance and durability, to flexibility and odorless extrusion. Our exhaustive catalog provides the choices you want to help you get the job done quickly and easily.

Quality

Torwell ABS filaments are loved by the printing community for their high-quality composition, offering clog, bubble and tangle-free printing. Every spool is assured to offer the highest caliber of performance possible. That’s the Torwell promise.

Colors

One of the most important factors of any print comes down to color. Torwell 3D colors are bold and vibrant. Mix and match bright primaries and nuanced hues with gloss, textured, sparkle, transparent, and even wood and marble-mimicking filaments.

Reliability

Trust all of your prints to Torwell! We strive to make 3D printing an enjoyable and error-free process for our customers. That’s why each filament is carefully formulated and thoroughly tested to save you time and effort every time you print.

| Density | 1.04 g/cm3 |

| Melt Flow Index(g/10min) | 12(220℃/10kg) |

| Heat Distortion Temp | 77℃, 0.45MPa |

| Tensile Strength | 45 MPa |

| Elongation at Break | 42% |

| Flexural Strength | 66.5MPa |

| Flexural Modulus | 1190 MPa |

| IZOD Impact Strength | 30kJ/㎡ |

| Durability | 8/10 |

| Printability | 7/10 |

| Extruder Temperature(℃) | 230 – 260℃Recommended 240℃ |

| Bed temperature(℃) | 90 – 110°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | LOW for better surface quality / OFF for better strength |

| Printing Speed | 30 – 100mm/s |

| Heated Bed | Required |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |