Flexible 95A 1.75mm TPU filament for 3D printing Soft Material

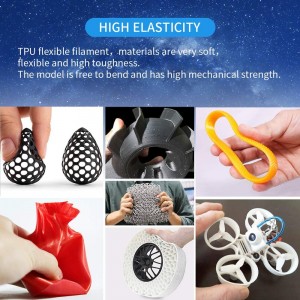

Torwell FLEX TPU has a Shore hardness of 95 A, and has a massive elongation at break of 800%. Benefit from a very wide range of applications with Torwell FLEX TPU. For example, 3D printing handles for bicycles, shock absorbers, rubber seals and insoles for shoes.

Product Features

| Brand | Torwell |

| Material | Premium grade Thermoplastic Polyurethane |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.05mm |

| Length | 1.75mm(1kg) = 330m |

| Storage Environment | Dry and ventilated |

| Drying Setting | 65˚C for 8h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

Torwell TPU filament is featured by its high strength and flexibility, like a hybrid of plastic and rubber.

95A TPU has high abrasion resistance and low compression compared to rubber parts, especially at higher infill.

In comparison with most common filaments like PLA and ABS, TPU must be run much slower.

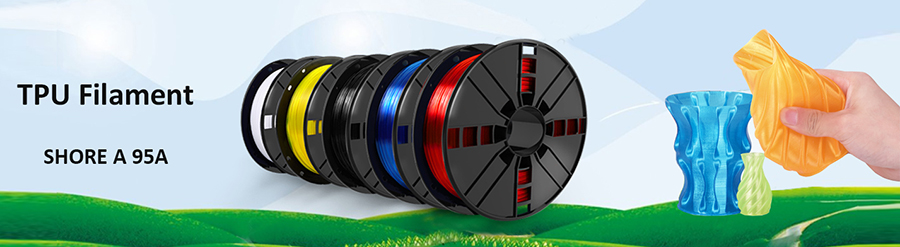

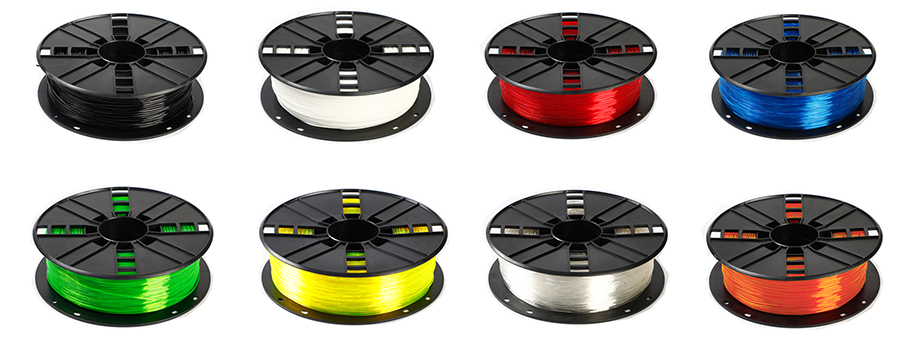

More Colors

Color available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Grey, Orange, Transparent |

|

Accept Customer PMS Color |

|

Model Show

Torwell TPU Flexible filament should be printed at lower speed than normal. And printing nozzle type Direct Drive (motor attached to the nozzle) due to its soft lines. Torwell TPU Flexible filament applications include seals, plugs, gaskets, sheets, shoes, key ring case for mobile hands-bike parts shock and wear rubber seal (Wearable Device/Protective applications).

Package

1kg roll 3D filament TPU with desiccant in vacuum package.

Each spool in individual box (Torwell box, Neutral box, or Customized box available).

8boxes per carton (carton size 44x44x19cm).

Make sure your TPU filament is stored in a dry place

Please note that TPU is hygroscopic, which means it tends to absorb water. Therefore, store it airtight and protected from moisture in a closed container or bag with a dehumidifier. If your TPU filament ever gets wet, you can always dry it for about 1 hour at 70° C in your baking oven. After that, the filament is dry and can be processed like new.

Certifications:

ROHS; REACH; SGS; MSDS; TUV

More Information

Torwell FLEX is versatile and can be used in a wide range of 3D printing applications, making it the perfect choice for anyone who needs a flexible filament that can meet their specific needs. Whether you're printing models, prototypes or final products, you can rely on Torwell FLEX to deliver consistently high-quality prints that meet or exceed your expectations.

Torwell FLEX is an innovative 3D printing filament that will definitely change the way you think about flexible filaments. Its unique combination of durability, flexibility and ease of use makes it perfect for a range of applications from prosthetics and medical devices to fashion accessories. So why wait? Get started with Torwell FLEX today and experience the best 3D printing has to offer!

High Durability

Torwell TPU flexible filament is a material that is soft and elastic like rubber, similar to the Flexible TPE but typing easier and harder than TPE. It allows for repeated movement or impact without cracking.

High Flexibility

Flexible materials have a property called Shore hardness, which determines the flexibility or hardness of a material. Torwell TPU has a Shore-A hardness of 95 and can stretch 3 times more than its original length.

| Density | 1.21 g/cm3 |

| Melt Flow Index(g/10min) | 1.5(190℃/2.16kg) |

| Shore Hardness | 95A |

| Tensile Strength | 32 MPa |

| Elongation at Break | 800% |

| Flexural Strength | / |

| Flexural Modulus | / |

| IZOD Impact Strength | / |

| Durability | 9/10 |

| Printability | 6/10 |

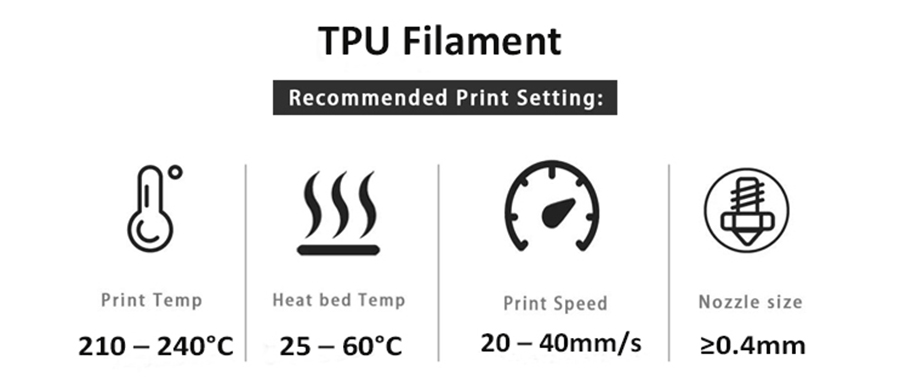

| Extruder Temperature(℃) | 210 – 240℃

Recommended 235℃ |

| Bed temperature(℃) | 25 – 60°C |

| Nozzle Size | ≥0.4mm |

| Fan Speed | On 100% |

| Printing Speed | 20 – 40mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |

| Recommended Build Surfaces | Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |

Recommended for printers with direct drive extruder, 0.4~0.8mm Nozzles.

With Bowden extruder you might pay more attention to these tips:

- Print slow 20-40 mm/s Printing speed

- First layer settings. (Height 100% Width 150% speed 50% e.g.)

- Retraction disabled. This would reduce messy, stringing or oozing printing result.

- Increase Multiplier (Optional). set to 1.1 would help the filament bond well. – Cooling fan on after first layer.

If you are having problems printing with soft filaments, firstly, and most importantly, slow the print down, run at 20mm/s will work perfectly.

It is important when loading the filament to allow it to only just start extruding. Once you see the filament coming out the nozzle hit stop. The load feature pushes filament through quicker than a normal print and this can cause it to get caught in the extruder gear.

Also feed the filament direct to the extruder, not through the feeder tube. This reduces the drag on the filament which can cause the gear to slip on the filament.