PLA 3D printer filament red color

Product Features

- Clog-Free & Bubble-Free: Designed and manufactured to guarantee a smooth and stable printing experience with these PLA refills. Complete drying for 24 hours before packaging and vacuum sealed with desiccants in a PE bag.

- Tangle Free & Moisture Fre: TORWELL Red PLA filament 1.75mm is carefully winded to avoid tangling issues. It is dried and vacuum-sealed in a PE bag with desiccant. Please pass the filament through the fixed hole to avoid tangles after use.

- Cost-effective and Wide Compatibility: With over 11 years'3D filaments R & D experience, thousands tons of filaments output every month, TORWELL is capable of manufacturing all kinds of filaments in large scale with premium quality, which contribute to 3d filament cost-effective and reliable for most common 3D printers, such as MK3, Ender 3, Monoprice FlashForge and more.

| Brand | Torwell |

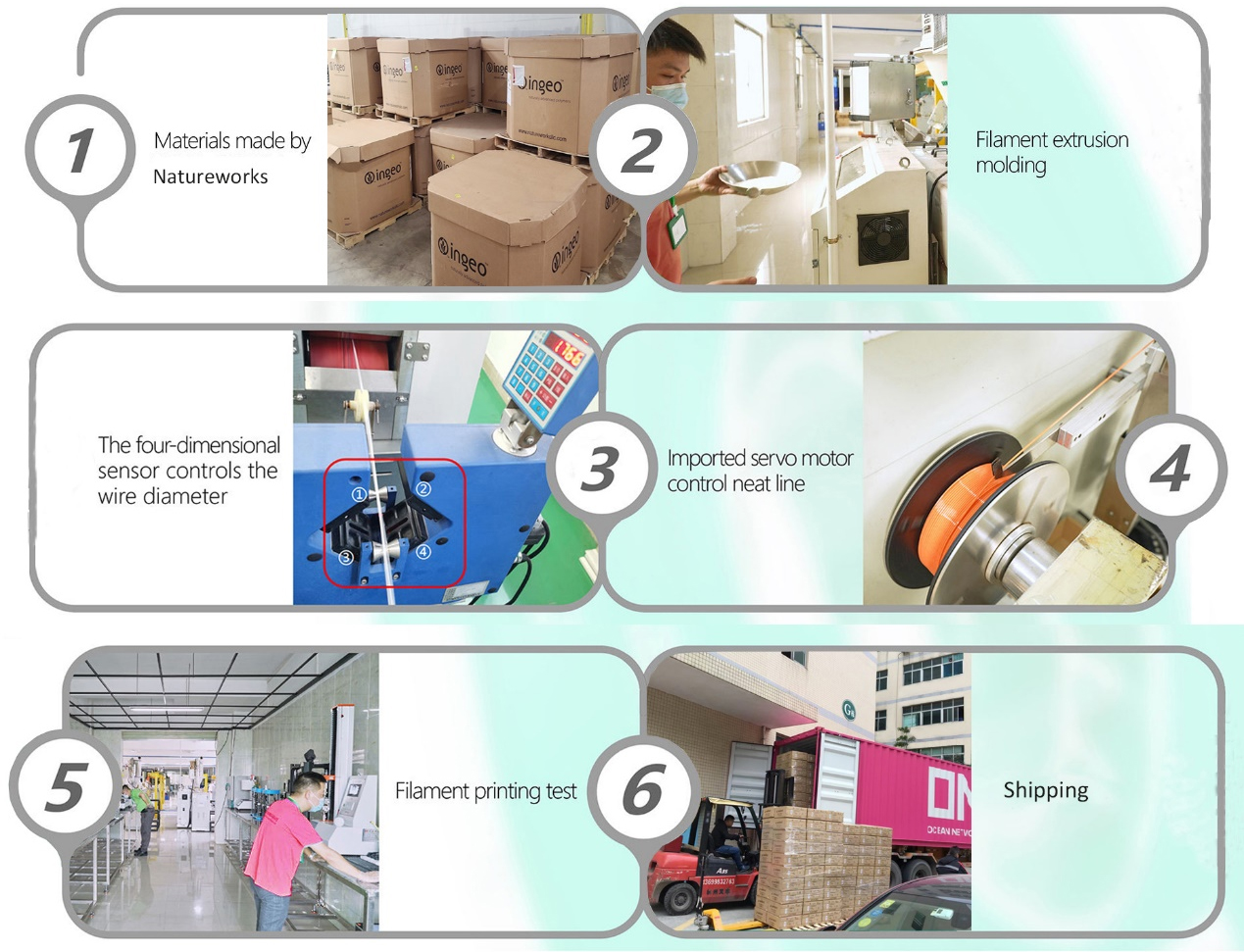

| Material | Standard PLA (NatureWorks 4032D / Total-Corbion LX575) |

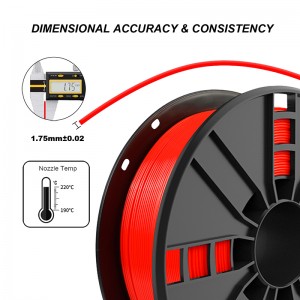

| Diameter | 1.75mm/2.85mm/3.0mm |

| Net weight | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Gross weight | 1.2Kg/spool |

| Tolerance | ± 0.02mm |

| Storage Environment | Dry and ventilated |

| Drying Setting | 55˚C for 6h |

| Support materials | Apply with Torwell HIPS, Torwell PVA |

| Certification Approval | CE, MSDS, Reach, FDA, TUV and SGS |

| Compatible with | Makerbot, UP, Felix, Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker and any other FDM 3D printers |

| Package | 1kg/spool; 8spools/ctn or 10spools/ctn sealed plastic bag with desiccants |

Charactors

* Clog-Free & Bubble-Free

* Less-tangle and Easy to Use

* Dimensional Accuracy & Consistency

* No Warping

* Enviroment friendly

* Widely use

More Colors

Color Available:

| Basic color | White, Black, Red, Blue, Yellow, Green, Nature, |

| Other color | Silver, Grey, Skin, Gold, Pink, Purple, Orange, Yellow-gold, Wood, Christmas green, Galaxy blue, Sky blue, Transparent |

| Fluorescent series | Fluorescent Red, Fluorescent Yellow, Fluorescent Green, Fluorescent Blue |

| Luminous series | Luminous Green, Luminous Blue |

| Color changing series | Blue green to yellow green, Blue to white, Purple to Pink, Grey to White |

|

Accept Customer PMS Color |

|

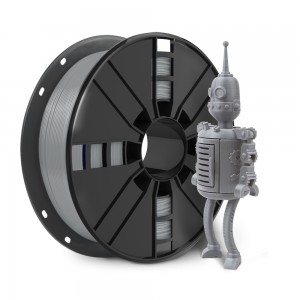

Model Show

Package

1kg roll PLA 3D printer filament with desiccant in vaccum package

Each spool in individual box (Torwell box, Neutral box, or Customized box avilable)

8boxes per carton (carton size 44x44x19cm)

Factory Facility

Tips for 3D printing

1. Level the bed

Before printing, you can use a sheet of paper to determine the distance between nozzle and bed at several points across the bed. Or you can install a bed-leveling sensor to automate the process.

2. Setting the ideal temperature

Different materials will have different ideal temperature. Also the enviroment will make the ideal temperature little difference. If the print temperature too high, the filament will be strings. While if too slow, it will not stick to the bed, or cause wrapping problem. You can adjust it according to the filament instuction or contact with our technical for support.

3. Cleaning with cleaning filament or changing the nozzle before printing is a effective way to reduce jam.

4. Store the filament properly.

Use the vaccum package or dry box to keep it dry.

Why doesn't the filament stick to the build bed easily?

- Temperature. Please check the temperature(bed and nozzle) settings before printing and set it suitable;

- Leveling. Please check if the bed is level, make sure the nozzle doesn't too far or too close to the bed;

- Speed. Please check if the printing speed of the first layer is too fast.

Contact with us for more details info@torwell3d.com.

| Density | 1.24 g/cm3 |

| Melt Flow Index(g/10min) | 3.5(190℃/2.16kg) |

| Heat Distortion Temp | 53℃, 0.45MPa |

| Tensile Strength | 72 MPa |

| Elongation at Break | 11.8% |

| Flexural Strength | 90 MPa |

| Flexural Modulus | 1915 MPa |

| IZOD Impact Strength | 5.4kJ/㎡ |

| Durability | 4/10 |

| Printability | 9/10 |

|

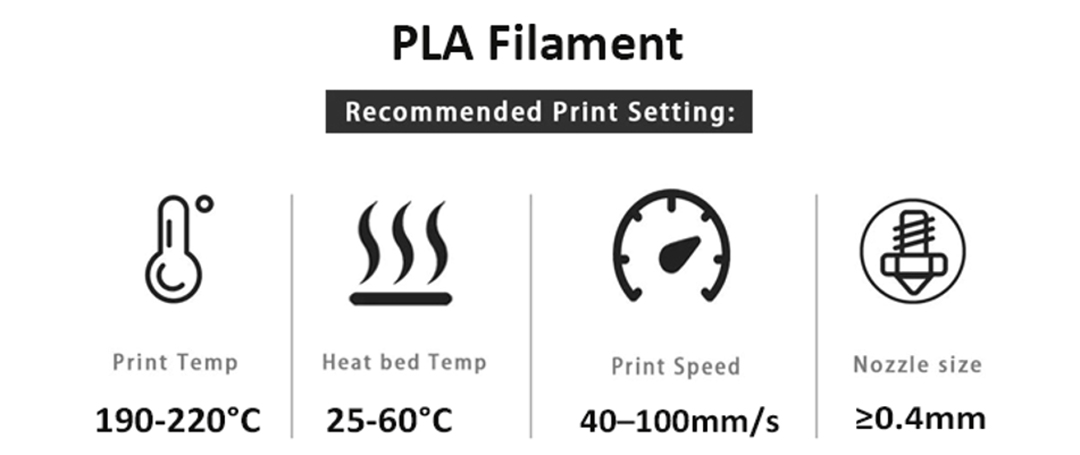

Extruder Temperature(℃) |

190 – 220℃ |

|

Bed temperature(℃) |

25 – 60°C |

|

Nozzle Size |

≥0.4mm |

|

Fan Speed |

On 100% |

|

Printing Speed |

40 – 100mm/s |

|

Heated Bed |

Optional |

|

Recommended Build Surfaces |

Glass with glue, Masking paper, Blue Tape, BuilTak, PEI |